In the world of printed circuit boards (PCBs), Gerber files play a critical role. These files contain the essential information required for manufacturing PCBs, serving as the blueprint for the production process. As the electronics industry continues to advance, adhering to best practices for creating and managing Gerber files is crucial for ensuring efficiency, accuracy, and high-quality results.

Here’s a comprehensive guide to help you navigate the intricacies of Gerber file management.

What Are Gerber Files?

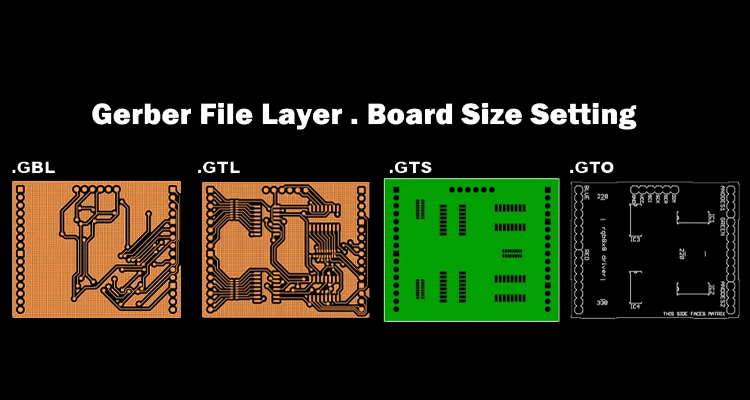

Gerber files are a set of standardized files used to describe the various layers of a PCB. Each file contains data for a single layer, such as copper traces, solder masks, or silkscreens. The standard format used today is the RS-274X, which supports additional features like apertures and attributes that enhance the detail and accuracy of the PCB design.

Best Practices for Creating Gerber Files

1. Use the Correct Software

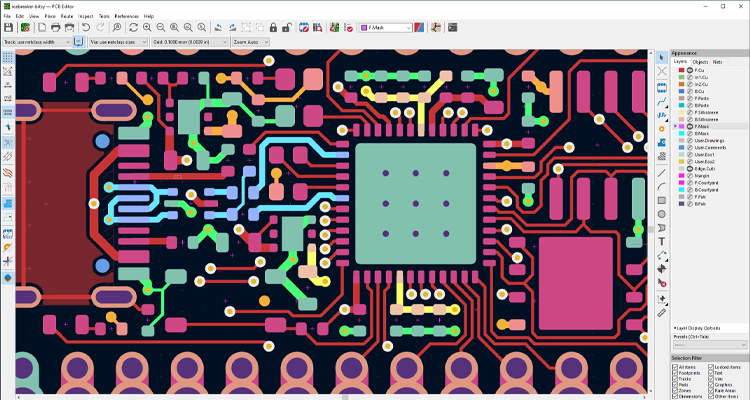

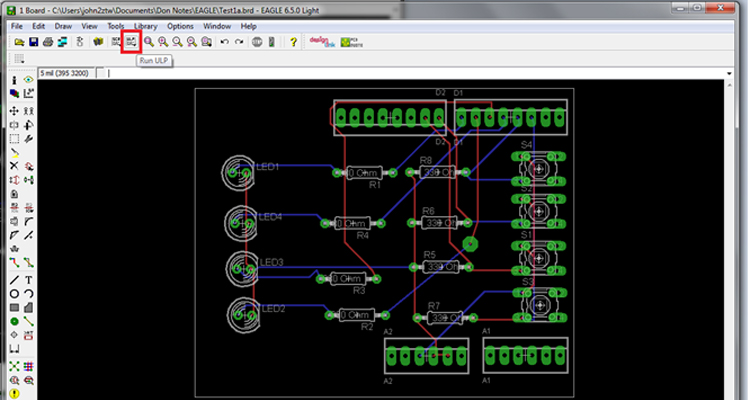

Choosing the right PCB design software is the first step. Software like Altium Designer, KiCad, and Eagle CAD are popular choices. These tools offer robust features for creating detailed and accurate PCB designs, and they support the RS-274X Gerber file format.

KiCad Software

Eagle CAD Software

2. Consistent Naming Conventions

Use a clear and consistent naming convention for your Gerber files. This practice minimizes confusion and ensures that each layer is easily identifiable.

3. Include All Necessary Layers

Ensure that all necessary layers are included in the Gerber files. Common layers include:

· Top and Bottom Copper Layers:

Contain the electrical connections.

· Solder Mask Layers:

Define the areas where solder will be applied.

· Silkscreen Layers:

Provide component labels and other markings.

· Drill Files:

Specify the locations and sizes of holes.

· Mechanical Layers:

Outline the PCB's physical dimensions and cutouts.

4. Verify Units and Formats

Ensure that your Gerber files use the correct units and formats. Typically, files should be in inches or millimeters with a precision of at least 2.4 (two integer digits and four decimal places) for accurate representation.

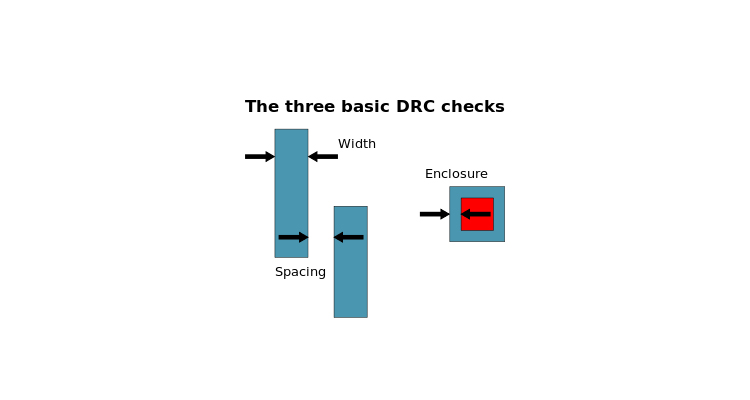

5. Perform Design Rule Checks (DRC)

Before exporting your Gerber files, perform a thorough Design Rule Check (DRC) within your PCB design software. This process helps identify potential issues like spacing violations, minimum trace widths, and other design constraints that could affect manufacturability.

Best Practices for Managing Gerber Files

1. Organize Your Files

Organize your Gerber files into a single, well-structured directory. Include a README file that lists all the included files and their purposes. This practice makes it easier for manufacturers to understand and use your files.

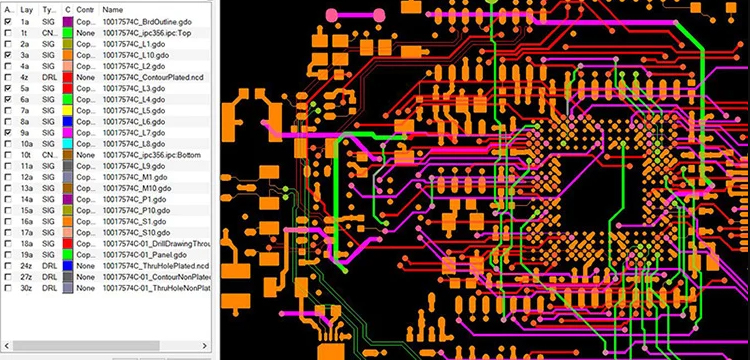

2. Use a Gerber Viewer

Before sending your files to the manufacturer, use a Gerber viewer to inspect each layer. Tools like Gerbv or online viewers provided by PCBGOGO can help you catch any errors or omissions that might have been missed during the design phase.

3. Communicate with Your Manufacturer

Effective communication with your PCB manufacturer is vital. Provide detailed documentation and instructions alongside your Gerber files. This documentation should include layer descriptions, stack-up information, and any special requirements or notes.

4. Version Control

Implement a version control system for your Gerber files. This practice helps track changes and ensures that you can revert to previous versions if needed. Tools like Git or even simple versioning in file names can be beneficial.

5. Backup Regularly

Regularly back up your Gerber files and associated project files can assure the possible mistakes in Gerber file which can lead to malfunctioning in PCB. Use cloud storage solutions or external drives to ensure that your data is safe from accidental loss or corruption.

Latest Trends and Technologies

1. Automated Gerber Verification

Modern PCB manufacturing increasingly utilizes automated Gerber verification tools. These tools check for common issues such as missing files, incorrect formats, and potential manufacturing problems, streamlining the pre-production process.

2. Integration with CAD/CAM Systems

The integration of Gerber files with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems enhances accuracy and efficiency. This integration allows for seamless transitions from design to production, reducing errors and improving turnaround times.

3. Advanced File Formats

Beyond the traditional Gerber format, new formats like ODB++ and IPC-2581 are gaining traction. These formats encapsulate more detailed information about the PCB design, reducing the likelihood of misinterpretation and errors during manufacturing.

Conclusion

Creating and managing Gerber files effectively is essential for the successful production of PCBs. By following these best practices, you can ensure that your designs are accurately translated into high-quality PCBs, minimizing errors and production delays. Stay updated with the latest tools and technologies to continually improve your PCB design and manufacturing processes.

For more detailed guidance and services, consider partnering with industry experts like PCBGOGO, who offer comprehensive support for all your PCB manufacturing needs.

- Comments(11)

J****obu

Jul 02.2024, 01:49:21

s****new

Jul 01.2024, 14:47:30

**

Jun 28.2024, 12:59:52

Thanks for sharing this information. I really like your blog post very much free game candy clicker 2 online. You have really shared a informative and interesting blog post with people.

C****de3

Jun 27.2024, 21:07:43

Claude 3 is the latest version of Anthropic's AI assistant, designed to provide more natural, coherent, and useful interactions with users. Named after Claude Shannon, a key figure in the development of information theory

https://claude3.us/

C****de3

Jun 27.2024, 21:07:43

Claude 3 is the latest version of Anthropic's AI assistant, designed to provide more natural, coherent, and useful interactions with users. Named after Claude Shannon, a key figure in the development of information theory

https://claude3.us/

**

Jun 27.2024, 18:40:35

J****nfo

Jun 27.2024, 00:22:39

Y****mas

Jun 26.2024, 20:02:35

**

Jun 24.2024, 15:36:17

D****ski

Jun 23.2024, 19:25:06

Managing Gerber files well is crucial for getting your PCBs made correctly. Following these tips helps ensure your designs turn into high-quality PCBs with fewer mistakes and delays. Keep learning about new tools and technologies to keep improving your PCB designs and manufacturing process!

https://www.thehindu.com/brandhub/best-tarot-reading-websites-with-a-free-tarot-reading-online/article67892132.ece

D****ski

Jun 23.2024, 19:23:33

Effectively managing Gerber files is crucial for ensuring your PCBs are made correctly. These practices help in translating your designs accurately, reducing mistakes and delays. It's important to keep up with the latest tools and technologies to improve your PCB design and manufacturing processes continually. By doing so, you'll enhance the quality and efficiency of your PCB production.

________